ESD / Electrostatic Discharge Testing and EMI (Electromagnetic Interference) in Control Equipment for Manufacturing & Biomedical Equipment in Hospitals

214.912.4691

Decades ago when integrated circuits first came out in consumer products and computers, they were unusually susceptible to ESD or static discharges of electricity. These initial devices typically employed TTL or Transistor Transistor Logic, which is now considered a rather rugged technology compared to modern MOSFET (Metal Oxide Semiconductor Field Effect) transistors that have a thin gate oxide (sometimes as little as 1 nanometer) that is easily punctured by an errant voltage.

In most cases, the older TTL devices would simply latch or lock-up and a reboot was necessary along with a spray of Static Guard or some other anti-static chemical to prevent recurrence. Engineers designing these circuits got more experienced at designing them so that external discharges would not perturb the device, and for a long while, static electricity has not been a consideration except when replacing internal components on a board or in a computer.

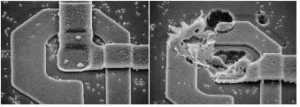

But with the numbers and density of the MOSFET transistors on an integrated circuit not only growing exponentially, it has become more sensitive because the feature sizes of the transistors themselves have grown smaller and smaller, well past the deep sub-micron range and into the low nanometer scale, and the unwelcome specter of ESD damage has returned. Even if not caused by a static discharge, it is not uncommon to find that a number of consumer electronics plugged into the wall socket has been permanently damaged after a severe thunderstorm or other electrical outage.

It only takes about 100 – 300 V of static electricity to damage a transistor, which is well below the threshold of 3000 V that you feel from a shock when touching a grounded metal object after walking across a carpeted floor on a cool, dry day. Sparks with voltages upwards of 30,000 volts are not uncommon under certain conditions and can easily wreak havoc on mission critical equipment.

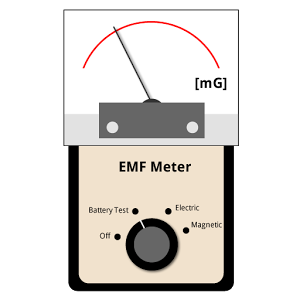

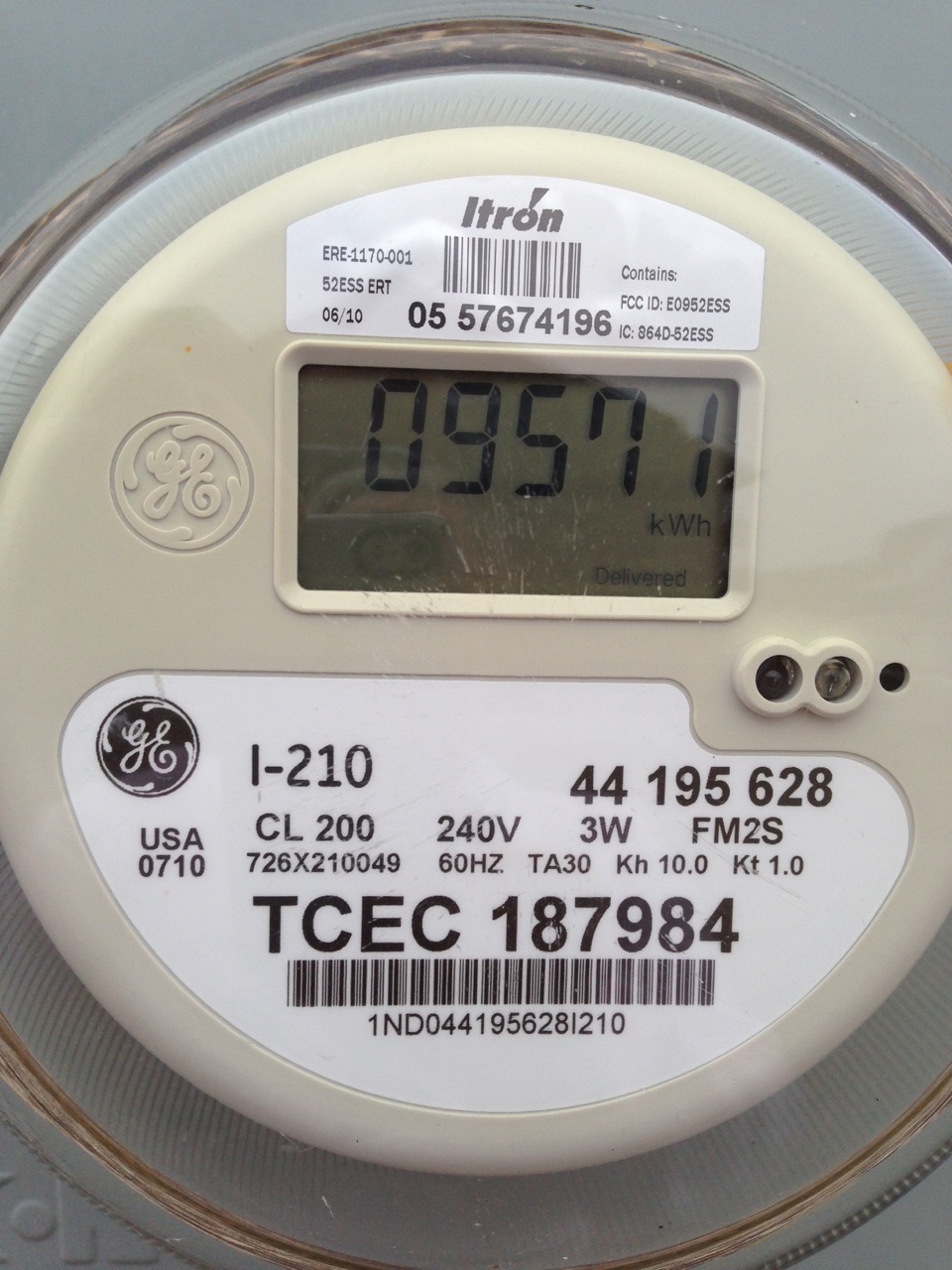

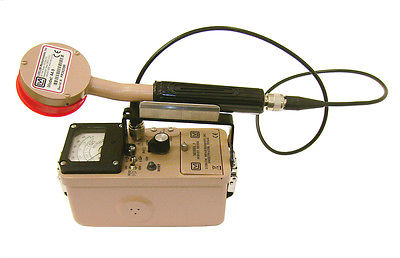

Contact ScanTech for an evaluation of your environment to detect conditions, materials and procedures that may be causing equipment malfunction, employee / patient shock incidents and possible explosion hazards in hospitals, clinics, biomedical labs, warehouses, data centers and areas with expensive and sensitive equipment as well as potential flammables. Data is derived from special instruments such as air ion counters, charge sensors and surface resistivity meters which are designed to measure static electricity and the effectiveness of anti-static protocols such as static dissipative vs. static conductive so as to be used to suggest the best course(s) of action.

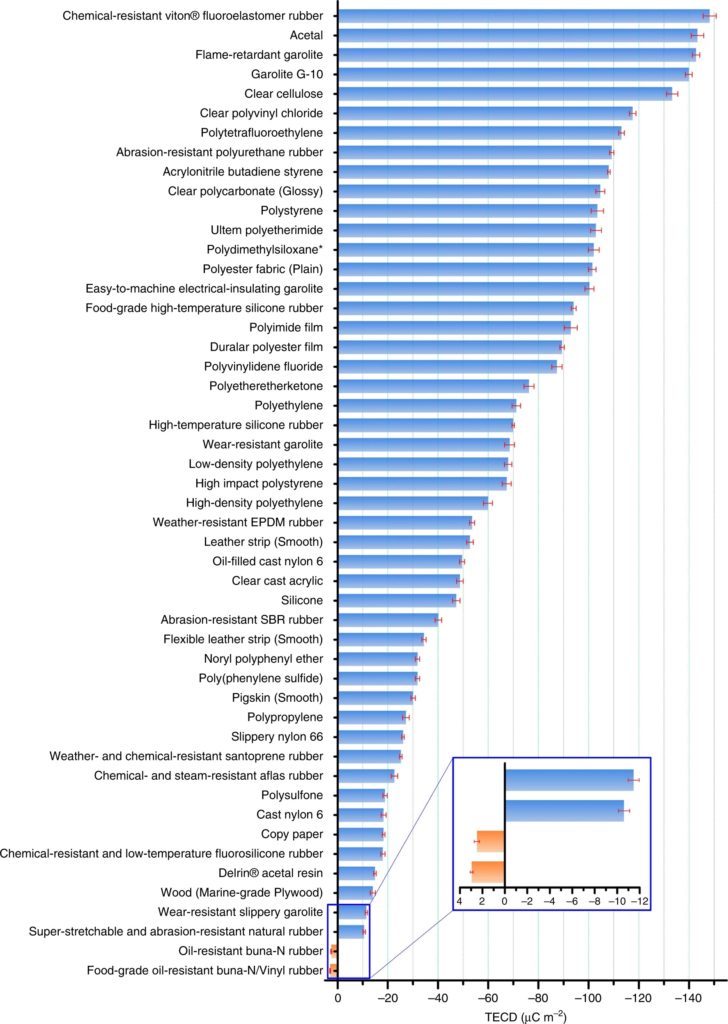

ESD Electrostatic Discharge Triboelectric Materials Charge Density Chart in microColoumbs / m^2

https://incompliancemag.com/article/electrostatic-hazards-in-healthcare/

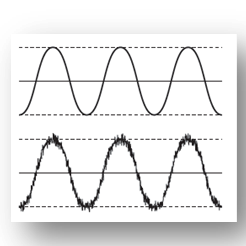

Comparison of a “Clean” Powerline Signal (top) with one that has EMI or High Frequency Noise (bottom)

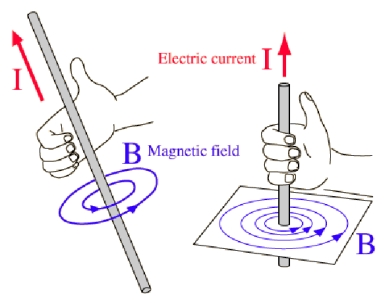

Electromagnetic Field Interference Surveys / EMI Testing & Consulting

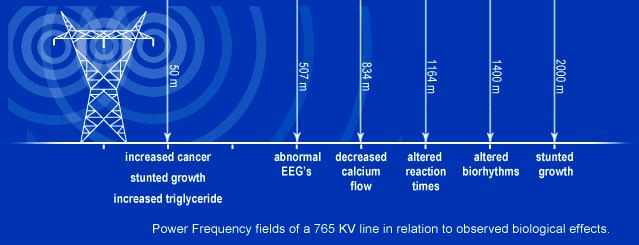

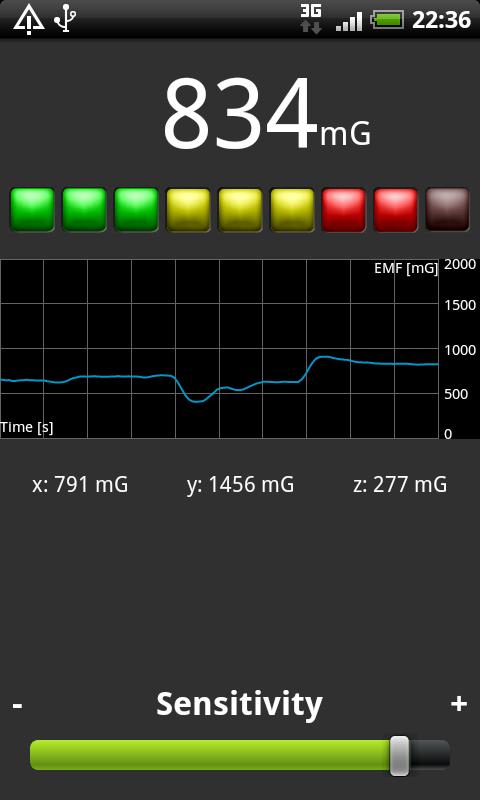

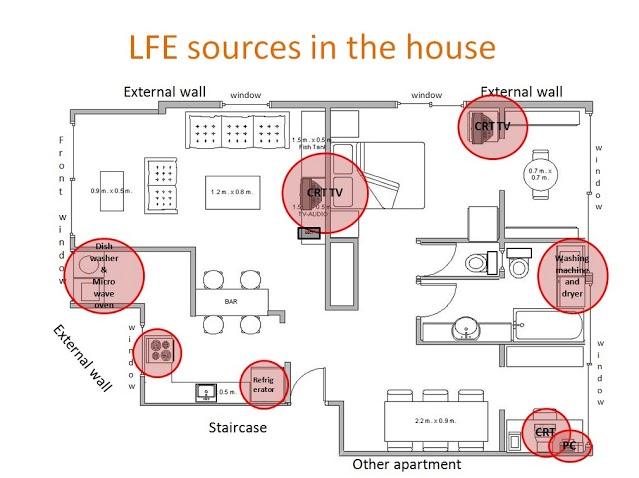

In addition, ScanTech has the equipment to measure and perform a variety of electromagnetic field (AC / DC / RF) EMF and EMI testing as well as the detection of harmful radioactive material.

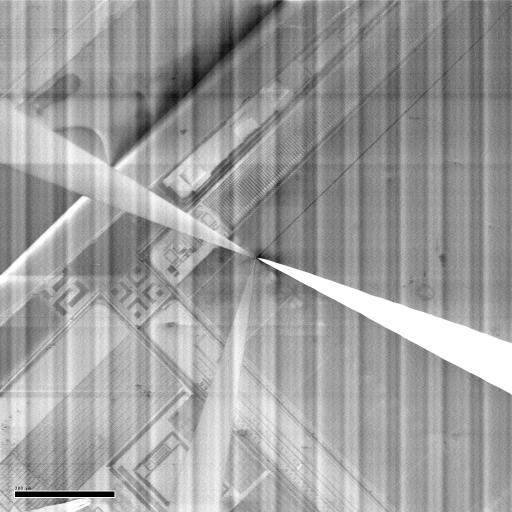

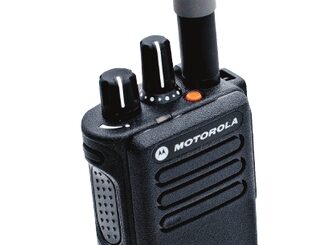

We are experienced in troubleshooting EMI / EMC (Electromagnetic Interference / Electromagnetic Compatibility) Problem Diagnosis & Resolution of Computer & Equipment Interference due to RF and grounding / ground loop issues in server rooms, near RF sealers, MRI equipment, SEM (Scanning Electron Microscopes), sensitive nanotechnolgy equipment, semiconductor manufacturing, etc.

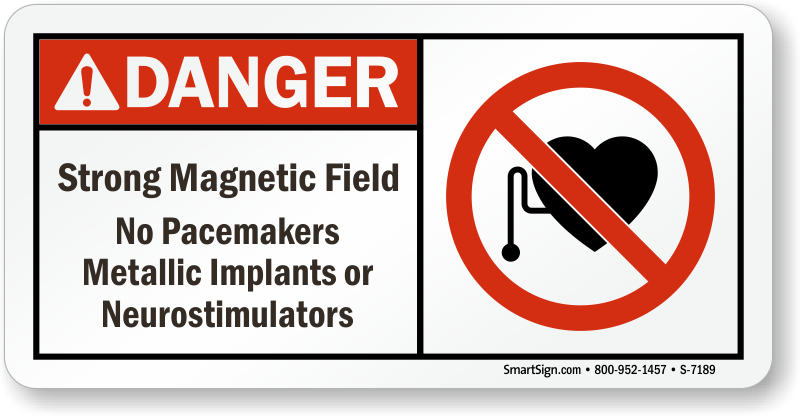

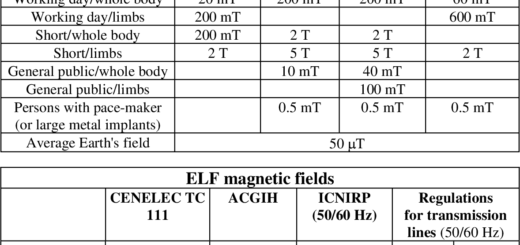

Medical Device / Biomedical Equipment EMF / EMI Compliance Testing: We have performed numerous surveys for companies and corporations with pacemaker / implantable defibrillator / ICD interference concerns for all major manufacturers of these devices. We have also done interference testing for EEG, EKG, Holter units (ambulatory EKG) and other biomedical equipment.

60 Hz Banding Scanning Electron Microscope EMI

What if it isn’t EMI? (Electromagnetic Interference) ScanTech can still assist in troubleshooting and discovering what is really going on due to our extensive interdisciplinary background. In many cases, the client assumes the problem is due to some external field, but the real issue can often be something unexpected and even less expensive / easier to fix than thought. A fresh insight from a highly experienced interdisciplinary consultant can rapidly resolve your nightmare scenario at great cost savings.

ESD / Electrostatic Discharge Links

Prostat University Webinar Series on ESD

https://www.prostat-university.com/Online-Courses/ESD-Coordinator-Training

WHO OR WHAT COMPANY DOES ESD TESTING NEAR ME?

ScanTech Technical Consulting provides professional ESD testing in the Dallas – Fort Worth, Houston, Austin and San Antonio areas of Texas to detect and measure exposure to ionizing, nuclear or atomic radiation. Call 214.912.4691

WHO OR WHAT COMPANY DOES ELECTROSTATIC DISCHARGE TESTING NEAR ME?

ScanTech Technical Consulting provides professional ESD testing in the Dallas – Fort Worth, Houston, Austin and San Antonio areas of Texas to detect and measure exposure to ionizing, nuclear or atomic radiation. Call 214.912.4691

WHO OR WHAT COMPANY DOES ELECTRICAL INTERFERENCE TESTING NEAR ME?

ScanTech Technical Consulting provides professional radio frequency (RF) testing in the Dallas – Fort Worth Texas area to detect and measure exposures to all forms of electromagnetic radiation. Call 214.912.4691

WHO OR WHAT COMPANY DOES PACEMAKER EMI TESTING AND ELECTRICAL INTERFERENCE SURVEYS FOR IMPLANTED BIOMEDICAL DEVICES NEAR ME?

ScanTech Technical Consulting provides professional EMI testing for pacemakers and other biomedical implants throughout the United States to detect and measure exposures to all forms of interference from electromagnetic radiation. Call 214.912.4691

LARGER COMMERCIAL PROJECT SERVICE RANGE – NATIONAL & INTERNATIONAL

Alabama | Alaska | Arizona | Arkansas | California | Colorado | Connecticut | Delaware | Florida | Georgia | Hawaii | Idaho | Illinois | Indiana | Iowa | Kansas | Kentucky | Louisiana | Maine | Maryland | Massachusetts | Michigan | Minnesota | Mississippi | Missouri | Montana | Nebraska | Nevada | New Hampshire | New Jersey | New Mexico | New York | North Carolina | North Dakota | Ohio | Oklahoma | Oregon | Pennsylvania | Rhode Island | South Carolina | South Dakota | Tennessee | Texas | Utah | Vermont | Virginia | Washington | West Virginia | Wisconsin | Wyoming | Washington D.C. (District of Columbia)

Countries include the United States, Canada, Australia, New Zealand the United Kingdom (England, Scotland, Wales, Ireland) and Western Europe.

*LEGAL NOTICE*

All information on this website either written or implied is the express opinion of ScanTech Technical Consulting. ScanTech Technical Consulting and it’s owners are not responsible or liable for any damages arising from the misuse, misinterpretation or other consequences of the content of this website either in part or in whole. This includes all external weblinks, PDF documents, photos or other references (informational or otherwise) to 3rd parties including government agencies, health organizations, etc.

15770 Dallas Parkway Suite 900 Dallas, TX 75248 (Not Accepting Visitors due to C19)

Phone: (214).912.4691 http://www.emfsurvey.com

ScanTech Technical Consulting: Professional Electromagnetic EMF Biomedical Implant & Equipment Indoor Air Quality Testing & Environmental Inspections

COPYRIGHT 2002 – 2024

Hello, My name is Mike Sours, I am the Sr. Engineering Manager at Merz for the Medical Device team. We have recently re-located from Mesa, AZ to Sturtevant, WI and have a small workcell that requires ESD setup/controls. We are looking for a consultant to come onsite and help us establish the the ESD environment.

Thank you Mike

Mr. Mike Sours,

Thank you for contacting ScanTech Technical Consulting regarding your need for ESD setup & controls for a biomedical manufacturing environment at Merz North America!

Please send the scope of work, desired specifications, timeline, etc. and I will get back with you on what ESD controls and equipment are appropriate for your needs.

Best Regards,

JAG of ScanTech